All maneuvers must be done on two independent rope systems. These two systems can work in parallel (two haul lines) or separately (work rope and belay rope).

1. Examples of hauling with work rope and belay rope.

All hauling and positioning forces are concentrated on the work rope. The belay rope is set up and kept taut enough to hold the load in the event of anchor or work rope failure.

Advantages

- Quick and simple setup, only one mechanical-advantage system needed.

- Two different systems may be used, for example a mechanical haul system (winch…).

- Configuration suited to small work spaces.

Disadvantages

- If the work rope breaks, the clearance needed can be significant when the belay rope comes under load.

- Risk of developing slack in the belay rope by focusing too much on the primary system.

- Risk of neglecting the quality of the belay system setup. Warning: this system must be fully operational at all times.

- Risk of the rope path shifting and of unforeseen abrasion on the belay rope as it comes under load following a work rope failure.

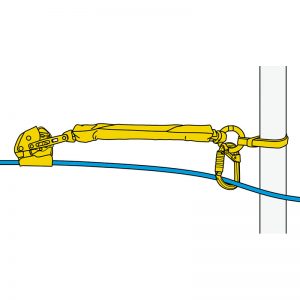

2. Examples of hauling with twin tensioned haul lines

The two ropes have the same function and work in parallel: each rope supports half the load.

Advantages

- With good coordination, it’s possible to haul a heavy load even with simple pulley systems.

- If one rope breaks, the other is already tensioned to hold the load, reducing the amount of clearance required.

- It is possible to manage a complex litter route if the rope paths are anticipated.

Disadvantages

- Load sharing between the two ropes is never perfect; sometimes one rope holds the entire load; good coordination of team members is required.

Reviews

There are no reviews yet.